Oak Crest Services

Biomedical Manufacturing

Oak Crest has broad experience in biomedicine ranging from pharmaceutical science to developing and prototyping instrumentation.

These products are assembled and manufactured in our Instrumentation Development and Biomedical R&D Facilities. Examples include:

CNC milling machine

Request Services

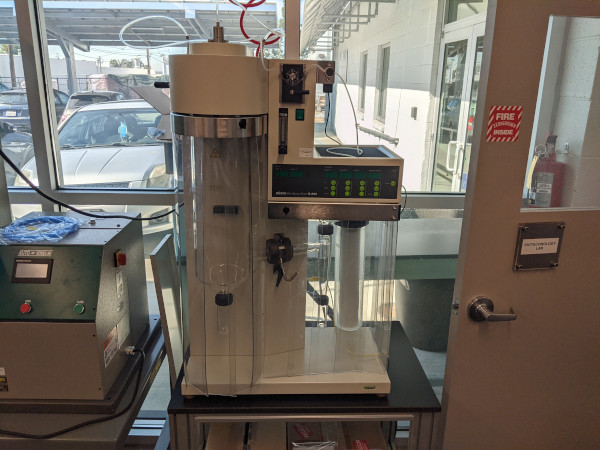

Buchi Mini spray dryer

Spin coater